مسكن

>

Cement production electrical diagram

مسكن

>

Cement production electrical diagram

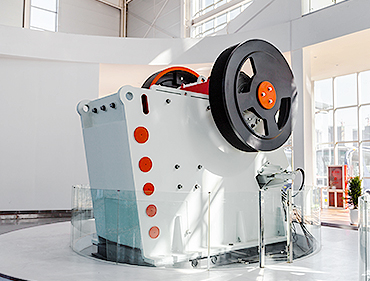

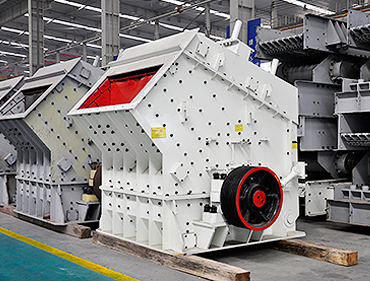

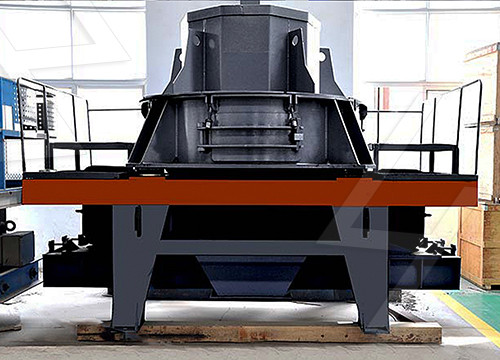

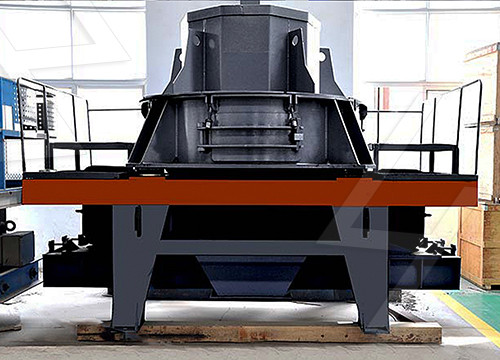

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Cement production electrical diagram

Process flow diagram for the cement manufacturing

According to [39], Figure 4 provides a process flow diagram of the general cement production process and the associated inputs, during various steps of the production process. consumption of ...

获取价格

Monitoring Control Systems for Cement Plants - Fuji Electric

Monitoring Control Systems for Cement Plants. Enabling stable operations by using optimal electrical equipment and monitoring and control systems to optimally control material

获取价格

Cement Manufacturing Process - INFINITY FOR CEMENT

Schematic representation of a cement manufacturing process

Figure 3 is a schematic representation of the cement manufacturing process, showing the electrical-energy-intensive processes and emissions. The following subsections describe

获取价格

Use of electrical energy in cement production [1,4]

The cement industry is an energy-intensive industry with energy typically accounting for 30–40% of production costs. Figure 1 presents the distribution of electricity demand in each stage of the ...

获取价格

IELTS Task 1 Process- Cement and Concrete Production

2015/4/14 The diagrams illustrate the phases and apparatus to make cement and how cement is utilised in the production of concrete for construction. The production of cement involves a 5 stage, linear process that begins with

获取价格

How the electrical systems in cement plants work

2021/3/3 Cement Mill; In the last 25 years, variable speed drives (VSD) have been used more frequently in the cement industry. The main reason was to save energy in the production process. MV and LV Drives in a Section.

获取价格

Decarbonization of cement production by electrification

2023/11/1 Notwithstanding the fact that CO 2 capture will be necessary to avoid process emissions from CaCO 3 calcination, electrification of heat supply is an interesting option to

获取价格

The Cement Plant Operations Handbook - International

Philip A. Alsop, PhD. perations Handbook SEVENTH EDITIONThe Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference

获取价格

The Cement Plant Operations Handbook - International

passivation – 13. Cement quality – 14. Setting time – 15. ASTM cement types and specifications – 16. European EN 197 cement specification – 17. Composite cements (intergrinds and blends) – 18. Supersulphated cement – 19. Calcium aluminate cement (CAC) – 20. Shrinkage-compensating cements (SCC) – 21. ISO 9001:2000 Quality 8.

获取价格

PROCESS ENGINEERING FOR THE CEMENT LIME

Cement Lime Mining Grupo ARGOS CEMEX Ultracem Cerro Matoso (BHP-Billiton) PERÚ Cement Lime Mining UNACEM Cementos Yura Cementos Otorongo Cemento Pacasmayo GlencoreXstrata Buenaventura Minera IRL Southern Peru Copper Corp. CHILE Cement Lime Mining Cementos San Juan Polpaico (Lafarge-Holcim) Cementos Bio Bio Minera Cal Norte

获取价格

Optimizing Energy Utilization in the Cement Industry: An

Energy cost in Indian cement Industry account for over 40 - 50 % of the manufacturing cost of cement. Out of this the share of thermal energy alone in the form of fuel is about 30 – 35 % while the remaining 15-20% accounts for mainly electrical energy the other relatively smaller ones being explosive, diesel, etc.,.

获取价格

IELTS Task 1 Process- Cement and Concrete Production

2015/4/14 The diagrams illustrate the phases and apparatus to make cement and how cement is utilised in the production of concrete for construction. The production of cement involves a 5 stage, linear process that begins with the mixing of raw materials and culminates in the packaging of new cement. ... The third paragraph looks at cement production in ...

获取价格

CEMEX and Synhelion ace the First “Hot Solar” Cement Trial

2022/4/12 About 95% of the CO2 emissions in cement production come from these two steps, the calcination and the clinkerization. Only about 5% comes from powering the grinding process, which uses electricity. This is a major breakthrough for solar heat, building on research from the SolPART project that CEMEX was involved in. At the time, Gilles Flamant ...

获取价格

(PDF) Process Automation of Cement Plant - ResearchGate

2012/4/30 The cement industry is an energy intensive industry consuming about 4 GJ per tonne of cement produced. A thermodynamic analysis for cogeneration using the waste heat streams is not easily available.

获取价格

How the electrical systems in cement plants work

2021/3/3 Our team of engineers regularly carry out electrical work at Quarries and Cement Plants, so are experienced and qualified in the industry. We have broken down the main 6 processes of a cement plant for you: Stage 1. Raw materials are extracted from quarries by blasting or using heavy machinery. They are then transported to the crushing plants ...

获取价格

Energy and Cost Analysis of Cement Production Using the

In Nigeria, cement production grew rapidly from 2 million tonnes in 2002 to 17 million in 2011 [4]. This has led to the Nigeria cement industry accounting for 63.6% of the West African region’s cement output in 2011. Daily production is in excess of sales having recorded a zero importation from January 2012 to date and in the

获取价格

Cement manufacturing process flow diagram - ResearchGate

In contrast, electricity-related emissions are generated by the During cement production, CO 2 is released from four different sources: emissions from the calcination of calcium carbonate ...

获取价格

Electrical power distribution in cement production processes.

Download scientific diagram Electrical power distribution in cement production processes. from publication: CONVENTIONAL CLINKER GRINDING -A NEW APPROACH TO THE PREDICTION OF POWER CONSUMPTION ...

获取价格

Mining Activities, Cement Production Process and Quality Control

2022/7/4 The industry started manufacturing cement in 1997 bringing into the cement market two brands called AKSHAR and BUILDPLAST cement. ... Flow diagram of production department Cement. ... The raw mill ...

获取价格

The generation of power from a cement kiln waste gases: a case

2017/4/1 The cost of energy keeps on fluctuating and this negatively impact on the manufacturing cost and eventually lowers the competitiveness and profitability of the cement industry. The energy costs in a cement industry account for about 26% of the total manufacturing cost of cement which is in the form of electrical energy accounting for 25% of the ...

获取价格

Cement industry PPT - SlideShare

2015/1/12 The document discusses the Indian cement industry. It notes that cement is used for construction purposes like buildings, transport infrastructure, and water systems. The main raw materials used are limestone, sand, shale, clay, and iron ore. The manufacturing process is highly energy intensive. Major players in the Indian cement industry are ...

获取价格

Cement Industry in Sri Lanka - JRTE

2020/1/2 Cement manufacturing process flow diagram [3] Table 1. Sri Lanka’s Cement Manufacturing sub processes Cement production sub process Inputs Outputs 1.Extraction of raw ... Cement enhancers, electricity Cement powder,

获取价格

Mining Activities, Cement Production Process and

2022/7/4 The industry started manufacturing cement in 1997 bringing into the cement market two brands called AKSHAR and BUILDPLAST cement. ... Flow diagram of production department Cement. ... The raw mill ...

获取价格

The generation of power from a cement kiln waste

2017/4/1 The cost of energy keeps on fluctuating and this negatively impact on the manufacturing cost and eventually lowers the competitiveness and profitability of the cement industry. The energy costs in a cement industry

获取价格

Cement industry PPT - SlideShare

2015/1/12 The document discusses the Indian cement industry. It notes that cement is used for construction purposes like buildings, transport infrastructure, and water systems. The main raw materials used are limestone,

获取价格

Cement Industry in Sri Lanka - JRTE

2020/1/2 Cement manufacturing process flow diagram [3] Table 1. Sri Lanka’s Cement Manufacturing sub processes Cement production sub process Inputs Outputs 1.Extraction of raw ... Cement enhancers, electricity Cement powder,

获取价格

Cement manufacturing process (% of electricity consumption

Download scientific diagram Cement manufacturing process (% of electricity consumption referred to tons of cement) from publication: Methodological development for the optimisation of ...

获取价格

The use of electrical energy in cement production (see online

Download scientific diagram The use of electrical energy in cement production (see online version for colours) from publication: ENERGY, EXERGY AND EXERGOECONOMIC ASSESSMENT OF A DRY TYPE ROTARY ...

获取价格

Band 6: The diagram below shows the stages and equipment used in cement ...

The diagram illustrates the process required to produce cement and how it this material used for the production of concrete. Overall, different materials are treated with heat and grinded to produce cement. At the same time, cement is mixed with other material to create concrete. For cement production, limestone and clay are needed.

获取价格

Clinker and cement production process Download Scientific Diagram

Download scientific diagram Clinker and cement production process from publication: Specific energy consumption of cement in Thailand According to the 2015 Thai Energy Conservation Plan, the ...

获取价格

Power generation in white cement plants from waste heat

2021/12/1 Cement industry is an energy intensive industry with energy typically accounting for about 30–40% of production cost. Producing one ton of cement consumes about 3–5 GJ as thermal energy -obtained from burning of fuel-as well as 90–150 kWh of electricity.

获取价格

World Cement production from 1990-2008 from [ 1].

Download scientific diagram World Cement production from 1990-2008 from [ 1]. ... The system was implemented on a South African plant where the electrical energy cost of cement reduced by 25% ...

获取价格

Cement plant on autopilot: a practical guide to success

The pressures facing manufacturing industries, such as the cement industry, are well known and often discussed in the pages of trade magazines and industry conferences. Similarly, the benefits of digitalization and Industry 4.0 have been much advertised by suppliers and users, keen to position themselves at the forefront of industry development.

获取价格

Electrical energy consumption for various phases in the cement industry ...

The electrical energy consumption for various phases in cement production is shown in Fig. 1. The grinding process of coal, raw material, and cement consumes 40%-70% of cement mill power consumption.

获取价格

Electricity intensity of cement (kWh/Mt) for Nigerian

Download scientific diagram Electricity intensity of cement (kWh/Mt) for Nigerian, global benchmark and Chinese benchmark cement plants utilizing wet, semi-wet, and dry manufacturing processes ...

获取价格

Product and technology – Cambridge Electric Cement

This co-production process avoids both the kiln-related energy and calcination process emissions from conventional cement production, and leverages existing steelmaking infrastructure. Product CEC’s cement product targets a direct replacement for current Portland Cement (i.e. a CEM I), delivering equivalent performance without the negative ...

获取价格