مسكن

>

typical dia of coal crusher

مسكن

>

typical dia of coal crusher

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

typical dia of coal crusher

The Differences Between Double Roll Crushers and

2020/3/24 The Double Roll Crusher is the more cost-effective option of the two. The main differences that make up the majority of the cost differences is the drive configurations. Since the Double Roll Crusher is V-belt driven, lower

获取价格

Coal Crusher Types- Impact Double Roller Crusher - AIMIX GROUP

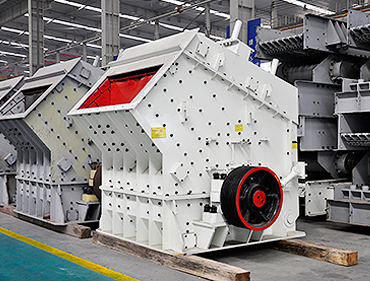

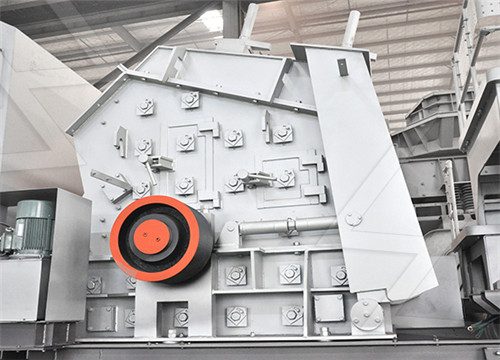

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture

获取价格

Performance assessment of the coal crusher machine using

A coal crusher is an important machining unit in a power generation unit, it crushes coal into the ... Troughing angle λ 35 0 Average spacing of the return idlers a u 3 m Forward tilling angle of

获取价格

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

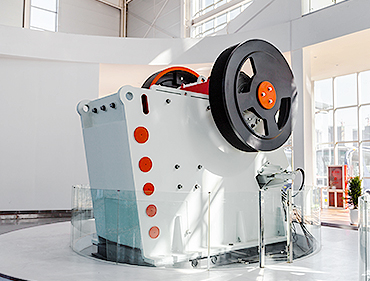

Jaw crusher. The jaw crushers are popular primary crushers for coal. They

Roll Crushers - TAKRAF

C: Crusher; 25: 2,500 mm - pitch circle roll diameter; 37: 3,700 mm - roll length; Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing applications

获取价格

Primary Crusher - an overview ScienceDirect Topics

9.3.1 Coal Crusher Classifications. In general, coal crushers are categorized into two types and three types of primary crushers, as follows: Primary coal crusher: Used for larger coal size.

获取价格

Experimental study on particle size distribution of impact crushed

2022/10/1 The average particle size of XQ coal sample decreases by 59.87% far more than that of ZZ by 19.43%, which is about three times. Furthermore, the average diameter of

获取价格

How Do I Know Which Primary Crusher Is Best For My

2019/10/17 Generally, a Quad Roll Crusher is recommended for a medium size feed material, while the Triple Roll Crusher, with its single roll top stage, is effective for handling larger size feeds. These machines do the work normally

获取价格

A Comparison of Three Types of Coal Pulverizers - Babcock

As shown in Figure 2, coal and preheated primary air first enter the crusher section. Here the coal is im- pacted on a grid section by swing hammers, reducing the coal to a nominal 1/4" size.

获取价格

sbm/sbm typical dia of coal crusher.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

获取价格

VIBRATING SCREEN RING GRANULATOR.pptx

2023/8/27 7. GENERAL DESCRIPTION DESCRIPTION: Coal feed from Upstream Conveyor BCN-7A/7B directly to the Vibrating Screen .The Chute gap kept between 600-700mm for smooth discharge of coal to crusher followed by

获取价格

Name already in use

sbm typical crushers of coalCoal Crusher Typical nocowaniepolanczyk average cost of coal crusher nigeria usfnsbe.a crusher is a machine designed to reduce large rocks into

获取价格

2022/sbm typical crusher of coal.md at main naicha22/2022

Contribute to naicha22/2022 development by creating an account on GitHub.

获取价格

A Comparison of Three Types of Coal Pulverizers - Babcock

As shown in Figure 2, coal and preheated primary air first enter the crusher section. Here the coal is im- pacted on a grid section by swing hammers, reducing the coal to a nominal 1/4" size. Drying of the coal also occurs in this section. After the coal passes through the grid section, it enters the two-stage pulverizing sec- tion.

获取价格

1. A crusher is used to crush coal. The product of Chegg

1. A crusher is used to crush coal. The product of the crusher is sieved. The undersize extracted sieve is picked as product. The results of the sieving product are mesh %mass -35 +48 0 -48 + 65 24.6 -65 + 100 18.3 -100 + 150 14.1 -150 + 200 10.5 -200 32.5 100 a. Calculate estimation of the average particle diameter of the crusher particles b.

获取价格

EXPERIMENT:- Jaw Crusher - LE COLLEGE

• Feed the above sample of coal to a jaw crusher and crush it. Measure the time for crushing. ... Average diameter Mass fraction (xi) ΣXi/Dpi Calculations: 1. Specific surface area Aw = (6/Qs Pp) Σ(x/Dp,) = = 2. Mass mean diameter Dw = Σx, Dp; = = 3. Volume surface mean diameter

获取价格

Crusher Efficiency Calculations - 911Metallurgist

2014/9/16 Considering a 30-in. diameter roll crusher the maximum size particle that can be nipped with the roll crusher set at 1 in. according to this Equation is F = 0.085(15) + 1.0 = 2.28 in. <3½ in. feed. It will take larger than a 40-in. diameter roll crusher.

获取价格

Experimental study on particle size distribution of impact crushed coal

2022/10/1 The average particle size of XQ coal sample decreases by 59.87% far more than that of ZZ by 19.43%, which is about three times. Furthermore, the average diameter of the coal sample XQ decreased more obviously, indicating that its coal impact crushing was affected more by the gas pressure.

获取价格

Modelling of output and power consumption in vertical shaft impact crushers

2008/8/1 The crusher used in the laboratory was similar to the crusher located at the test plant, but the laboratory crusher is smaller in size. ... average diameter of the inlet (m) k. constant (–) d. particle diameter (m) r I. ... size fractions in coal and gas outbursts through theoretical and experimental investigation into the shape of fine coal ...

获取价格

Roll crushers PPT Free Download - SlideShare

2015/4/24 Coal plants will use roll crushers, either single roll or double roll, as primary crushers, reducing the ROM coal. 6. ROLL CRUSHER CIRCUIT DIAGRAM 7. SINGLE ROLL CRUSHERS 8. ... 1M IN DIAMETER ,ARE SET SO THAT THE CRUSHING SURFACES ARE 12.5mm APART AND THE ANGLE OF NIP IS 31.WHAT IS THE MAXIMUM SIZE OF

获取价格

Optimization of particle size distribution in circulating fluidized ...

2019/6/15 Properties of coal gangue feed, especially its particle size distribution (PSD) and variable hardness, result in considerable impacts on both the efficiencies of the circulating fluidized bed (CFB) boiler and wastage of crushers.These two aspects are addressed in this study. First, the Aspen Plus software was used to optimize the coal gangue crushing system

获取价格

sbm/sbm diameter of crushed coal.md at main brblmd/sbm

Contribute to brblmd/sbm development by creating an account on GitHub.

获取价格

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017/3/4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

获取价格

Roll Crushers - TAKRAF

C: Crusher; 25: 2,500 mm - pitch circle roll diameter; 37: 3,700 mm - roll length; Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing applications at up to 1,500 kW of motor power. Each gearbox is manufactured and tested at our workshop in Lauchhammer, Germany.

获取价格

Optimization of particle size distribution in circulating fluidized ...

2019/6/15 Properties of coal gangue feed, especially its particle size distribution (PSD) and variable hardness, result in considerable impacts on both the efficiencies of the circulating fluidized bed (CFB) boiler and wastage of crushers.These two aspects are addressed in this study. First, the Aspen Plus software was used to optimize the coal gangue crushing system

获取价格

sbm/sbm diameter of crushed coal.md at main brblmd/sbm

Contribute to brblmd/sbm development by creating an account on GitHub.

获取价格

SIZE REDUCTION BY CRUSHING METHODS

2017/3/4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

获取价格

Roll Crushers - TAKRAF

C: Crusher; 25: 2,500 mm - pitch circle roll diameter; 37: 3,700 mm - roll length; Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing applications at up to 1,500 kW of motor power. Each gearbox is manufactured and tested at our workshop in Lauchhammer, Germany.

获取价格

Crushing of coal and calculation of size reduction efficiency.

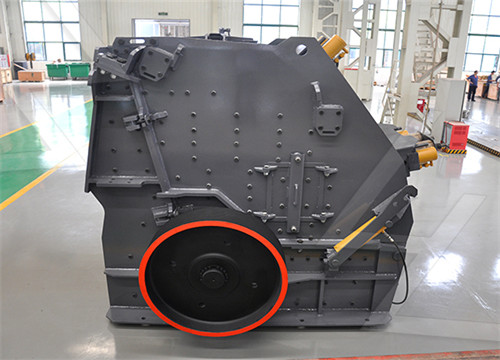

2015/2/25 The document discusses the history and evolution of coal crushers. It begins with an overview of the importance of crushing coal and the early developments starting in the 1800s. Key crushers discussed include the Cornish rolls, jaw crushers, gyratory crushers, single and double roll crushers, rotary breakers, impact crushers, and hammer mills.

获取价格

Coal Crushing in Ring Granulator Crusher #CoalCrushing

观看视频4:332022/4/30 This video is about how coarse coal is crushed in Ring Granulator crushers to reduce its size. Crushing reduces the size of coal up to 20 mm, which is furthe...

获取价格

Coal Crusher Types- Impact Double Roller Crusher - AIMIX

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. ... Rotor diameter (mm): Φ1200*1400; Feed opening size (mm): 450*1440; Max Feeding size (mm): 400; Processing capacity (t/h): 130-200; Mixing power ...

获取价格

Particle size distribution analysis of ground coal by machine

2011/1/1 Coal fines had several applications, such as gasification, liquefaction, combustion, and beneficiation, but also pose health and safety hazards. Particle size and particle size distribution (PSD ...

获取价格

Optimization of particle size distribution in circulating fluidized ...

2019/6/15 The results were applied in optimizing an industrial-scale crushing system and two-toothed roll crusher of a coal gangue-fired power plant. Investigations demonstrated that the PSD can improve the combustion efficiencies of the CFB significantly by 3%, as well as a 3× extension of the original service life of the two-toothed roll crusher ...

获取价格

5000 Series Roll Crushers - Mecotra

The First and Only Roll Crushers Able to Size Coal, Salts, Potash, Lime and Soft Minerals in 3 Dimensions ... typical products are 100 mm, 50 mm, 38 mm, down to 6 mm depending on feed size; ... and 36" (915 mm) diameter rolls; Roll face up to 120" (3050 mm) wide; For sizing materials with compressive strength up to 22,000 PSI (152 Mpa) ...

获取价格

CHPL332 Tutorial - Size reduction of solids 1 - Studocu

The same machine is used to crush dolomite at the same rate of output from 6 mm diameter average size to a product which consists of 20% with an average diameter of 0 mm, 60% with an average diameter of 0 mm, the balance having an average diameter of 0 mm. Estimate the power required to drive the crusher, assuming that the crushing strength of ...

获取价格

Dust Control Handbook for Industrial Minerals Mining and

Dust Control Handbook for Industrial Minerals Mining and Processing Andrew B. Cecala, Andrew D. O’Brien, Joseph Schall, Jay F. Colinet, William R. Fox,

获取价格

PREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION

Figure 3.4 Stirrer diameter versus stirrer speed for different Metso Vertimill units ..... 63 Figure 3.5 (a) as-received aggregate, (b) jaw crusher product, and (c) roll crusher product ..... 66 Figure 3.6 Simplified grinding circuit flowsheet of a secondary operation using a 650HP-

获取价格

Primary Coal Crushers Grow to Meet Demand

2009/9/12 Moreover, crusher manufacturers are making improvements to the equipment that extends the life of the rolls and the average time between maintenance. In the eastern U.S., where a majority of the coal production is washed, primary crushers are usually reducing a 20- to 24-inch feed to a more easily conveyed 4- to 6-inch top size.

获取价格