مسكن

>

extraction of lime from limestone process

مسكن

>

extraction of lime from limestone process

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

extraction of lime from limestone process

Limestone Quarrying and Processing: A Life-Cycle Inventory

imestone Quarrying and Processing Operations2.1 LimestoneLimestone is a sedimentary rock composed primarily of c. lcium carbonate with the occasional presence of magnesium. Most

获取价格

Limestone extraction – underground mining techniques, drilling ...

11.17 Lime Manufacturing - US EPA

11.17 Lime Manufacturing 11.17.1 Process Description 1-5 Lime is the high-temperature product of the calcination of limestone. Although limestone deposits are found in every state, only a

获取价格

Production - European Lime Association

The whole process of making any type of lime all begins at the limestone quarry after careful surveys. Most limestone is extracted through blasting. Behind the rock face, holes are drilled

获取价格

A Life-Cycle Inventory of Limestone Dimension Stone

Specifically, the information that follows is an initial LCI characterizing limestone extraction and production operations in North America. These data will serve as a baseline from which

获取价格

Limestone and Crushed Rock - Department of Energy

One product of limestone mining is lime. A wide range of industries use lime for a myriad of uses. It is used in many of the products and materials Americans use every day, ... 9.1 Process

获取价格

(PDF) Environmental Hazards of Limestone Mining and

2020/2/18 The limestone mined is used chiefly for the manufacturing of cement, lime and edible lime etc. Scientific studies revealed that loss of forest cover, pollution of water, soil and air, depletion of ...

获取价格

How Limestone Is Extracted at Vetter Stone

2020/2/25 The actual extraction of limestone is made by separating the rock in quarry ledges and dividing it into blocks. Here is an overview of Vetter’s Stones extraction process: The overburden, or the material above the stone

获取价格

Investigation Study of Locally Production of Lime - IJSR

quick lime production process including extraction and preparing of limestone and burning it at high temperature (1200 - 1500) °C in a kiln, then cooling it by air, storing portion of it, and the

获取价格

EXTRACTION OF ALUMINA FROM IRAQI COLORED KAOLIN BY LIME-SINTER PROCESS

In this work lime -sinter method was investigated to recover alumina from Iraqi colored kaolinitic claystone. The claystone was intimately mixed with limestone and the mixture was sintered. The annealed sintered material dusts to a fine powder which required no grinding. This material was leached with sodium carbonate solution, and an alumina extract (sodium aluminate solution)

获取价格

Extraction of alumina from low-grade kaolin in the presence of lime

2022/11/1 Kaolinite (Al 2 O 3 2SiO 2 2H 2 O), which is widely distributed in kaolin, coal gangue and mill tailings, etc., is a common clay mineral that contains 39.49% Al 2 O 3 and 46.55% SiO 2 by molecular weight. Due to the relatively high Al 2 O 3 content, concentrated efforts have been put forward to study the extraction of alumina from the kaolinite-containing

获取价格

(PDF) Studying the Efficiency of Lime-Soda Sinter

2018/5/25 Generally, two processes have been proposed for Al 2 O 3 extraction from clays and low-grade aluminium ores: the first is an acid process that uses sulfuric acid, hydrochloric acid or nitric acid ...

获取价格

Limestone and Crushed Rock - Department of Energy

One product of limestone mining is lime. A wide range of industries use lime for a myriad of uses. It is used in many of the products and materials Americans use every day, ... 9.1 Process Overview 9.1.1 Extraction Most crushed and broken stone is mined from open quarries; however, in many areas, ...

获取价格

Understanding The Process of Limestone Lumps ZME ( Zohdy

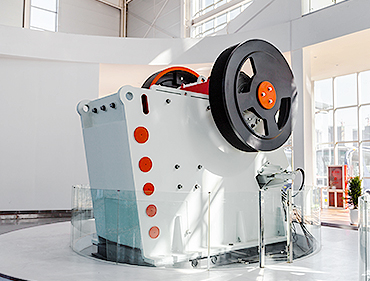

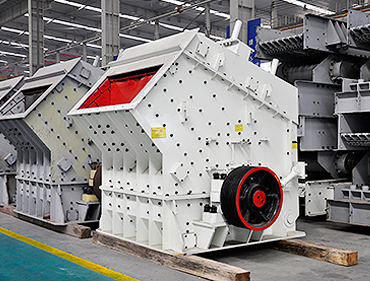

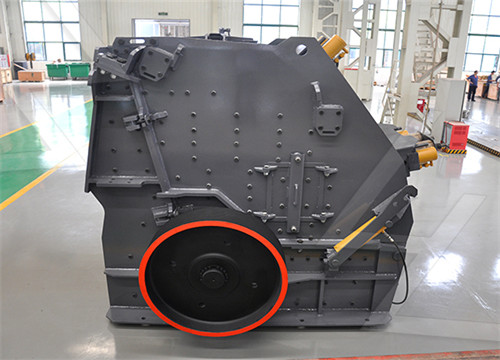

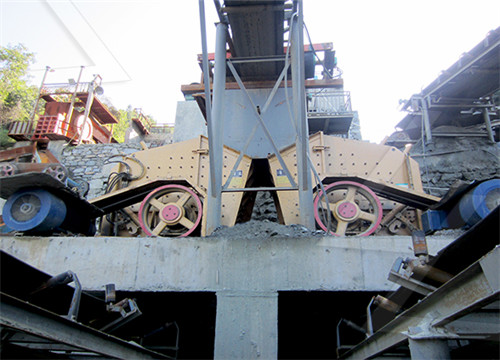

2024/9/26 Extraction Process of Limestone Lumps. The first step involves locating suitable limestone deposits in the earth’s crust, known for their high calcium carbonate content. ... is often used as a building material and in the manufacture of lime for various chemical processes. The crushing process typically involves two stages: primary and ...

获取价格

What is the role of lime or limestone in the extraction of Iron?

The chemical formula of limestone is CaCO 3. Limestone is a basic flux that can be used to form fusible slag from earthly impurities present in the ore. Limestone undergoes decomposition to form lime i.e. Calcium oxide (CaO) and Carbon dioxide. The decomposition reaction occurs as follows: CaCO 3 s Limestone → CaO s (Lime) + CO 2 g

获取价格

Process - Cales de Llierca

The Precipitated Calcium Carbonate cycle begins with the limestone extraction from our own quarry, followed by the Calcination and Hydration of selected materials which obtains the different lime qualities. The cycle is completed by carbonating the top quality lime with the CO2 generated in the previous calcination step to obtain the customized Precipitated Calcium Carbonates. []

获取价格

Extraction of alumina from kaolin by a combination of pyro- and

2019/5/1 Before the leaching process, the kaolin ore and limestone charge was sintered. The sintering process achieves the dehydroxylation of the kaolinite, which is the main mineralogical phase in the kaolin and activates its transformation to metakaolin. ... Studying the efficiency of lime-soda sinter process to extract alumina from colored kaolinite ...

获取价格

Flow diagram of the limestone scrubbing method.

In regenerative process, ... In lime and limestone scrubbing, calcium compounds are added as slurry to the scrubber liquid, and this can result in the formation of solid calcium salts. As a result ...

获取价格

(PDF) Factors affecting on the extraction of alumina from kaolin

PDF On Nov 12, 2019, A.B. ElDeeb and others published Factors affecting on the extraction of alumina from kaolin ore using lime-sinter process Find, read and cite all the research you need on ...

获取价格

(PDF) Studying the Efficiency of Lime-Soda Sinter Process to Extract

Studying the Efficiency of Lime-Soda Sinter Process to Extract Alumina from Colored Kaolinite Ores Using Factorial Technique of Design of Experiments ... were used in sintering and leaching processes. II. Experimental Procedure The kaolinite clay and limestone samples were crushed by a laboratory jaw crushed to pass 1 mm , then ground by ...

获取价格

Alkaline Process for Extracting Lithium from Spodumene

order to provide samples for mineralogical and chemical characterization and extraction assays. Calcitic limestone and lime were used as sources of calcium. The evaluation and control of the process were performed by X-ray diffractometry (XRD), gravimetry and flame atomic absorption spectroscopy (FAAS).

获取价格

A review of lithium extraction from natural resources - Springer

2.1.1. Lime roasting method The lime roasting method is the earliest method used to extract lithium from spodumene [27]. Spodumene is mixed with lime or limestone for roasting. Sufficient amount of CaO destroys the mineral structure at high temperatures over 1100°C [28–29]. The roasting reaction is shown in reaction (1).

获取价格

Lime use in gold processing – A review - ScienceDirect

2021/12/1 Lime is the generic term used to describe various formats of the reagent (National Lime Association, 1995; du Plessis et al., 2021).Formats include: quicklime – a dry reagent with calcium oxide (CaO) as the main component, produced from the calcination of limestone containing calcium carbonate (CaCO 3); hydrate or hydrated lime – a dry reagent

获取价格

(PDF) Studying the Efficiency of Lime-Soda Sinter

Studying the Efficiency of Lime-Soda Sinter Process to Extract Alumina from Colored Kaolinite Ores Using Factorial Technique of Design of Experiments ... were used in sintering and leaching processes. II. Experimental Procedure

获取价格

Alkaline Process for Extracting Lithium from Spodumene

order to provide samples for mineralogical and chemical characterization and extraction assays. Calcitic limestone and lime were used as sources of calcium. The evaluation and control of the process were performed by X-ray diffractometry (XRD), gravimetry and flame atomic absorption spectroscopy (FAAS).

获取价格

A review of lithium extraction from natural resources - Springer

2.1.1. Lime roasting method The lime roasting method is the earliest method used to extract lithium from spodumene [27]. Spodumene is mixed with lime or limestone for roasting. Sufficient amount of CaO destroys the mineral structure at high temperatures over 1100°C [28–29]. The roasting reaction is shown in reaction (1).

获取价格

Lime use in gold processing – A review - ScienceDirect

2021/12/1 Lime is the generic term used to describe various formats of the reagent (National Lime Association, 1995; du Plessis et al., 2021).Formats include: quicklime – a dry reagent with calcium oxide (CaO) as the main component, produced from the calcination of limestone containing calcium carbonate (CaCO 3); hydrate or hydrated lime – a dry reagent

获取价格

Limestone Crushing Process - JXSC Mineral

The hydrated lime is prepared into lime slurry, lime paste, etc., as coating materials and brick adhesives. Limestone can have various colors, ... The process begins with limestone extraction from a quarry or mine. This may involve drilling, blasting, and other methods to break the limestone into manageable sizes for further processing. ...

获取价格

Limestone Quarry Production Planning for Consistent Supply

strategy of the limestone quarries varies considerably from one quarry to another. The proposed case study focuses on to maximize the extraction of the low grade limestone i.e. Lime Saturation Factor (LSF) between 60 to 90 for the life of the quarry. Therefore, the

获取价格

Lime Production - an overview ScienceDirect Topics

Lime is mainly used in the production of cement, but also in cosmetics and pharmaceuticals. The solar process for the lime obtaining was studied by Flamant et al. (1980); Imhof (1997); Meier et al. (2004) and Meier et al. (2006). The energy required for the limestone calcination is calculated according to the following chemical reaction:

获取价格

Milk of Lime in sugar Industry MOL System Capacity Requirement

2024/10/3 The consumption of lime in different processes is as follows. In Defecation Process – 0.08 to 0.12% on cane; In Sulphitation Process – 0.14 to 0.20% on cane; The availability of lime in different forms like quick lime , limestone and hydrated lime

获取价格

Among the statements a d, the correct ones are:a Limestone is

Among the statements a d, the correct ones are:a Limestone is decomposed to CaO during the extraction of iron from its oxides.b In the extraction of silver, silver is extracted as an anionic complex.c Nickel is purified by Mond’s process.d Zr and Ti are purified by Van Arkel method.

获取价格

What is the role of Limestone in the extraction of iron from its

In the extraction of iron, a basic flux limestone is used. Limestone decomposes to form CaO which reacts with silica gangue present in the iron ore is acidic in nature to form calcium silicate (slag). \[\ce{CaCO3 -> CaO + CO2}\]

获取价格

Processing of lithium ores: Industrial technologies and case

2021/5/1 Today, the other schemes, such as sulfuric acid and calcareous (lime or limestone) (Neikov et al., 2019), have been identified as the main technological schemes for spodumene concentrates processing. Both schemes ensure the selective extraction of lithium, and the advantages (as well as disadvantages) of each scheme are determining by specific ...

获取价格

Limestone – The amazing scrubbing reagent - Power Engineering

2023/3/27 Figure 1. Generic wet-limestone FGD process flow diagram with an open spray tower. Illustration courtesy of ChemTreat, Inc. The general equation for the initial scrubber reaction is:

获取价格

Lime Production: Industry Profile - US EPA

description of the production process for lime, with discussions of individual lime products, limestone inputs, and costs of production. Section 3 describes the characteristics, uses, and consumers of lime as well as substitution possibilities. Section 4 discusses the organization of the industry and provides facility- and company-level data.

获取价格

Extraction of alumina from low-grade kaolin in the presence of lime

2022/11/1 Kaolinite as an aluminum-rich clay mineral is widely distributed in kaolin, coal gangue and mill tailings, etc. Herein, alumina extraction from the low-grade kaolin was explored via multi-stage hydrothermal process in the presence of NaOH and lime. In single stage, maximum alumina leaching ratio was found to be 33.64% in the presence of 20 g/L NaOH,

获取价格