مسكن

>

cement ball grinding mill

مسكن

>

cement ball grinding mill

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

cement ball grinding mill

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL

ncrease.Optimization of the Cement Ball Mill OperationOptimization addresse. the grinding process, maintenance and product quality. The objective is to achieve a more efficient

获取价格

Ball mill for cement grinding - Cement

Cement grinding with our highly efficient ball mill. An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy

获取价格

Cement mill - Wikipedia

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of high-chromium steel. The smaller grades are occasionally cylindrical ("pebs") rath

获取价格

Optimising Stirred Milling Technology World Cement

12 小时之 In 1984, high-pressure roller presses were developed, proving more energy-efficient than other conventional grinding methods. When used as a pre-crusher before ball mills, roller

获取价格

BALL MILLS Ball mill optimisation - Holzinger Consulting

to optimise the grinding process.Clinker grain sizes depend on pre-crusher settings but are in some cases still up to 50mm when fed to the ball mill and therefore, it is necessary to adju. t

获取价格

Ball mills Cement

Ball mill for cement grinding. An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and

获取价格

Ball Mill - thyssenkrupp Polysius

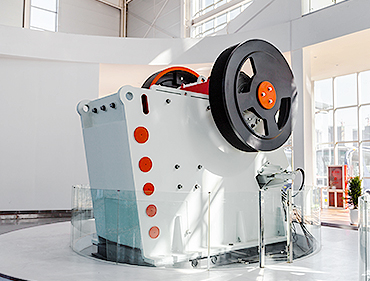

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable

获取价格

Cement Ball Mill Cost Effective Cement Grinding Mill

AGICO cement ball mills have a wide range of models, with a maximum output of 130 tons per hour, which can meet the production needs of large, medium, and small cement manufacturers. Based on the grinding system used by

获取价格

Grinding in Ball Mills: Modeling and Process Control - ResearchGate

2012/6/1 Mill. – Cement and Concrete Research, V ol. 33, 2003, 439-445. 16. D i n g, B. C. Modern Predictive Control. Taylor and Francis Group, 2010. ... Ball mills can grind a wide

获取价格

Ball Mill for Cement Grinding Process

Cement Ball Mill Structure. When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed. The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc.);

获取价格

BALL MILLS Ball mill optimisation - Holzinger Consulting

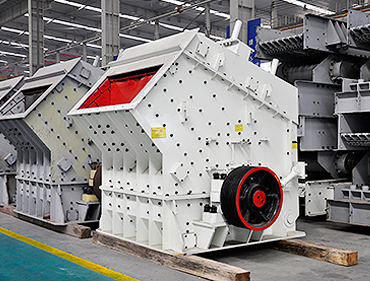

Ball mills and grinding tools Cement ball mills are typically two-chamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying liners.

获取价格

EVERY COMPONENT OF BALL MILL DETAILED

Insufficient mill cooling lead to material agglomeration on balls and liners. The grinding is not any more done by balls against material but by material against material. SOLUTION. Adapted mill cooling, playing with:-Clinker temperature

获取价格

Vertical roller mill vs. ball mill for cement grinding: Comparison

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant. VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainability.

获取价格

Grinding in Cement Manufacturing: Key Process, Types of Mills,

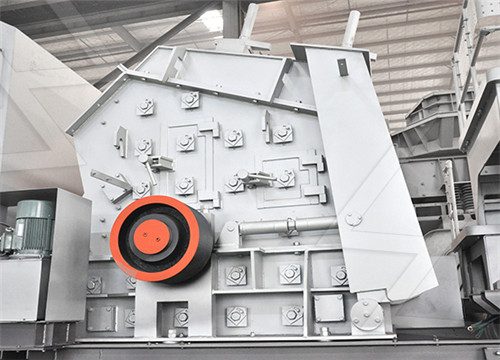

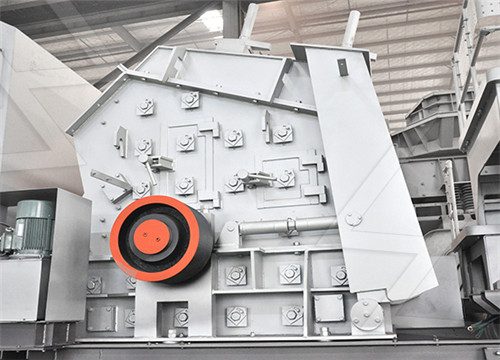

Types of Mills Used in Grinding 1. Ball Mills. Ball mills are one of the most commonly used types of equipment for cement grinding. They utilize steel balls as grinding media to crush and grind the raw materials into fine powder. The process operates in a continuous cycle: Material Feeding: The raw materials are fed into the mill.

获取价格

Cement Ball Mill Ball Mill For Sale Cement Mill 15-100t/h

The ball mill price is affected by the following factors, you can choose a suitable cement ball mill according to these factors. Cost of production: materials cost, human cost, electricity power cost, etc.; Technical costs: technology import, equipment optimization, and upgrading.; Capacity: more large-scale, more complete service, and more cost-effective.

获取价格

Ball Mill For Cement Grinding – Cement Ball Mill Ball Mill

Cement Ball Mill AGICO Adopt Efficient Cement Separator. The function of cement separator is to reduce the unnecessary grinding amount of cement ball mill and improve its grinding efficiency by screening out the particles with certain fineness in time. The key technologies of cement separators are dispersion, classification, and collection.

获取价格

Ball Mill - thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.. Used in combination with the sepol® high-efficiency separator, ball mills can reliably

获取价格

Predictive Controller Design for a Cement Ball Mill Grinding

2020/7/26 The annual cement consumption in the world is around 1.7 billion tonnes and is increasing by 1% every year [].Cement industries consume 5% of the total industrial energy utilised in the world [].A total of 40% of the total energy consumption of a cement plant is used in clinker grinding in a ball mill to produce the final cement product []. ...

获取价格

Cement Grinding Station Solution -Ball Mill and Vertical Mill

Cement Grinding Station Advantage. The new cement grinding station adopts the pregrinding technology, on the one hand to reduce the particle size of the material into the grinding; On the other hand to promote the material particles inside the crack and defect, so as to greatly improve the output of cement mill, reduce energy consumption.

获取价格

Ball Mill In Cement Plant - Cement Ball Mill AGICO Cement

The open-circuit grinding system of the ball mill is shown as follows: materials (including clinker, gypsum, mixed materials, etc.) mixed according to a certain proportion will be directly stored in the steel silo as finished cement products after being ground by the ball mill.

获取价格

Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer - Tongli

ISO9001、ISO14001、ISO45001 certified, accredited as High-tech new technology enterprise of Zhejiang Province, Tongli ZJTL series cement grinding equipment has won the Chinese National Torch Award.

获取价格

Cement Mill Cement Ball Mill Vertical Cement Mill - Cement

The cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other high-quality cement grinding machines for you! Skip to content +86 13683722138. info@cement-plants. about. blog.

获取价格

Cement Ball Mill Maintenance

BALL MILL INSPECTION PROCEDURE. source : thecementgrindingoffice Introduction. This document is intended to help the staff of the cement plants. On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working condition with a representative cement product.

获取价格

Ball charge optimization - INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP2.1 2 Description of the main indicators used in this BP2.1.0.1 The residue on 2mm/4mm before partition wall2.1.0.2 Material filling level and ball charge expansion2.1.1 Cement mill specific power 1st compartment 2.1.2 Raw mill specific power 1st compartment Ball charge

获取价格

Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer - Tongli

ISO9001、ISO14001、ISO45001 certified, accredited as High-tech new technology enterprise of Zhejiang Province, Tongli ZJTL series cement grinding equipment has won the Chinese National Torch Award.

获取价格

Cement Mill Cement Ball Mill Vertical Cement Mill

The cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other high-quality cement grinding machines for you! Skip to content +86 13683722138.

获取价格

Cement Ball Mill Maintenance

BALL MILL INSPECTION PROCEDURE. source : thecementgrindingoffice Introduction. This document is intended to help the staff of the cement plants. On a process point of view, a mill inspection is

获取价格

Ball charge optimization - INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP2.1 2 Description of the main indicators used in this BP2.1.0.1 The residue on 2mm/4mm before partition wall2.1.0.2 Material filling level and ball charge expansion2.1.1 Cement mill specific power 1st compartment 2.1.2 Raw mill specific power 1st compartment Ball charge

获取价格

Cement Production Seminar: Grinding - Cement

Ball mill for cement grinding. Gear Pinions. Girth Gear. STANEX Diaphragm for Ball Mill... Roller presses. Hydraulic Roller Press. Tribomax® Wear Surface. ... This 3-day seminar covers ball and vertical mills with a focus oncomminution theory, design basis, operational principles, control and regulation, process troubleshooting, calculation ...

获取价格

Process Training Ball Mill - INFINITY FOR CEMENT EQUIPMENT

Ball Charge. Ball mills for cement grinding usually operate with a filling degree between 25 and 35 %. The filling degree is defined as the volume of the grinding media (balls) as a percentage of the total mill volume. Since mill speed, liner shape and mill diameter are usually unchangeable parameters, the only adjustment in a mill can be made ...

获取价格

Ball Mill - cementgrindingmill

Raw Material Ball MillThis ball mill is mainly used for grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries. Besides, the raw mill has two forms of milling, one is an open form.

获取价格

`Grinding Aid Effectiveness in Cement Ball Mill - Academia

Introduction irst it is important to know the types of cement mills used in cement plant to grind the clinker (main Substance in cement production) to produce ordinary Portland cement (opc), mainly there are four types of mills: Horizontal Ball Mill in Closed Circuit, Vertical Roller Mill and other less using like Horo Mill, Vertical Ball Mill ...

获取价格

Cement Vertical Mill - Vertical Grinding Mill - Vertical Mill AGICO

What Is Cement Vertical Mill. The cement vertical mill is a type of grinding equipment that merges fine crushing, drying, grinding, and powder separating into a single, which simplifies the production process and has many irreplaceable advantages, such as high grinding efficiency, large feeding size, low power consumption (20-30% less power than a cement ball mill), large

获取价格

What Are the Parts of a Cement Mills? - Cement Ball Mill

2023/8/23 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder. This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement. To achieve this crucial transformation, a cement mill comprises

获取价格

Rod Mill - Ball Mill - Cement Milll AGICO Cement Equipment

Rod mill is a kind of cement ball mill used in cement plants. MBS series rod mills are used for further grinding after the raw material is broken. It is an essential machine widely used in the cement manufacturing plant. ... Rod mills and ball mills are two grinding mills with similar working principles. The biggest difference is that the ...

获取价格

5 Must-know Ball Mill Parts And Functions

The ball mill cylinder is a hollow barrel, which is rolled and welded by several steel plates. The two ends of the cylinder are connected to the ball mill trunnion with end covers. As the main part of the ball mill, it has to bear the weight of the lining plate, grinding media, compartment plate, and grinding materials.

获取价格

Grinding ball data - INFINITY FOR CEMENT EQUIPMENT

After long grinding of cement an increase in the C02-content was observed. After two hours of grinding, 2.7 % C02, and after 20 grinding hours 4.6% C02 was found, although initially no C02 was detectable. ... of the energy supplied to the mill destroyed on the lining independent of the mill’s revolutions and the mill’s grinding ball ...

获取价格

Optimization of Cement Grinding Operation in Ball Mills PEC ...

Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarse-grinds the feed material and prepares it for the second chamber. The

获取价格